Wastewater Tank Protection: material guidance

Because water tanks are susceptible to corrosion, they benefit from a liner or special coating. The choice can depend on what material the tank is composed of, its location, condition, and cost.

Whatever material is selected, it should create an impermeable barrier, fully adhere to the substrate, and seal all the gaps. In addition, manufacturers and distributors of any water treatment product, including liners, must comply with NSF/ANSI 61: Drinking Water System Components – Health Effects. Developed by a team of scientists, industry experts, and industry stakeholders, and implemented by government agencies that regulate drinking water supplies, NSF 61 established criteria for water system components, including:

- protective barrier materials (cements, paints, coatings);

- joining and sealing materials (gaskets, adhesives, lubricants);

- mechanical devices (water meters, valves, filters);

- pipes and related items (pipe, hose, fittings);

- plumbing devices (faucets, drinking fountains);

- process media (filter media, ion exchange resins); and

- non-metallic potable water materials.

TANK TECH

There are different corrosion requirements for different kinds of tanks, explains Davies Hood, president, Induron Protective Coatings. If the tank contains potable water, he points out, it’s not as corrosive as processed water in waste treatment plants. Birmingham, AL, the company’s home city, is an old steel manufacturing hub where there is plenty of corrosion. This explains why the niche manufacturer began formulating coatings for the water and wastewater industries.

Traditional paint systems consisted of three coats of epoxy: 3–5 mil for a total of 12 mil of protection. But the technology is evolving. Now, a one-coat system can be up to 30 mil. That results in reduced labor costs as well as the diminished possibility of inner coat adhesion failure.

Induron produces NSF 61-approved epoxy tank linings for water storage, including the PermaClean 100 (100% volume solids), solvent-free epoxy that provides a protective barrier of up to 30 ml in one coat, and ceramic epoxy TL 70 (70% volume solids).

Hood says others offer instant-setting polyurethane, but that Induron manufactures products that don’t leach into the drinking water. “I advocate solvent-free epoxy linings that protect the substrate by creating a uniform film—a barrier coating.” Depending on the ambient conditions and preparation, the coating can last more than 20 years in immersion with no concerns about solvents leaching or solvent entrapment, which affects the life of the system.

Epoxy is more forgiving of weather conditions and the resin is good at wetting-out a substrate, Hood says. “The substrate doesn’t need to be perfect to perform; that saves on cost. The surface doesn’t have to be as clean with epoxy as with other products.”

Another benefit of epoxy is that VOCs don’t go into the air, following federal environmental regulations and even stricter regulations in California, Delaware, Washington DC, and Maryland. “You don’t have to deal with isocyanates—polyurethane and polyuria—which are dangerous to the guys doing the work,” points out Hood, adding that polyurethane is not used much in potable water, except in concrete tanks, because it bridges cracks, and in ground storage tanks out west.

“There’s a lot to the technology behind tank linings,” continues Hood, explaining that American Water Works Association (AWWA) committee D102, made up of industry experts that recommends systems, recently endorsed a new ICS6 inside coating system. “They don’t update often,” he notes. The new two-coat interior lining almost doubles the film thickness of the tank lining, for a 20-year service life. Hood calls it “corrosion protection for less applied cost.”

A change he sees in the industry is the increase of 100% solids solvent-free epoxy linings in one to two coats. A solvent-free system is applied with different equipment that is typically more expensive, but the widespread availability of that equipment and the fact that “people are getting better at applying it” has contributed to its usage.

LONG LIVE THE LINER

The choice of liner depends on what is contained, claims Mike Baron, president, BTL Liners. He says polypropylene is typically used for potable water, especially in aboveground storage tanks because it’s good at alleviating weeping. Polypropylene is a good long-term solution for concrete cistern liners, while polyethylene is more of a short-term fix.

BTL is a large fabrication and production facility in Oregon, capable of fabricating up to half a million square feet of reinforced polyurethane, polypropylene liners per day in its state-of-the-art 84,000-square foot facility.

While coatings are done onsite by a crew using a spray-on bed liner-type material, liners are fabricated in one piece in the facility. “We weld it in the facility and ship it to the job site, where we roll it out from accordion folds,” explains Baron. Equipment is used to pull it up on the vertical, after which attachment mechanisms such as clips or belly cables are placed around the perimeter to secure it. After it’s in place, it doesn’t need a lot of downward pressure; the fluid keeps the liner taut.

There are shipping limits, so BTL will send a tech to weld the 8,000-pound panels together. “It’s easy to put a certified welding tech on a plane and get local labor to help with the field seams,” says Baron. The tech performs extrusion welding to encapsulate the edge with the weld. Different scenarios have different requirements. For example, big tanks need supports in the middle.

The 40-mil PW3 is potable grade and NSF 61-approved, so there is no leaching out, Baron says. “There’s little ability for moisture to get through 40 mil polypropylene.” Other materials wick moisture like condensation through to the dry side, with enough depth and pressure in a process known as hydrostatic water transfer, but the HDPE polyester permits no leaching.

It comes with a 20-year UV warranty from the manufacturer. “UV degrades plastic covering storage reservoirs when it’s exposed,” points out Baron. In addition to an extended warranty, he says the PW3 enjoys a long lifetime in part because it’s made in a controlled environment, as opposed to coatings applied in the field where weather (wind, rain) is a factor.

Another factor contributing to the liner’s longevity is the fact that it’s made from virgin resins in North America. “Recycled materials cost less, but may have impurities that can cause potential delamination,” elaborates Baron. “Lasting longer is a big issue. Failure is a bigger issue when you factor in labor costs, material costs, downtime, potential litigation, and potential contamination. That’s why we choose quality versus lowest cost.”

Pre-fabricated liners are also available for homeowners to self-install. “It’s simple,” says Baron. An anchor bolt with a washer can be screwed in, or a nail gun can be used with a concrete cistern.

COVERING UP

Many reservoirs in the open-top potable water industry use floating covers to reduce or eliminate evaporation. “The evaporation rate is high in large reservoirs, except in the middle of the country, which gets ample rain, so storage is not as critical,” says Steven Roades, vice president, Burke Environmental. But for some places, such as California, the East Coast, and the Caribbean, where underground cisterns are used because rain is the only source of potable water, water storage is critical. “It can be hundreds of gallons; that’s substantial. Water is expensive.”

To combat evaporation, Burke introduced its patented tensioned and floating covers. Made of chlorosulfonated polyethylene (a synthetic rubber noted for its resistance to chemicals, temperature extremes, and UV rays), this geo-membrane comprises 45% of Burke’s membranes.

“Twenty years ago, urethane-based and silicone-based coatings were good, but the technology has gotten better,” says Roades. He says that today, CSPE geomembranes are the king of liners for potable water.

The rubber polymer is flexible—and remains so over the product’s lifetime, without significant loss of mass after 30 years. Roades says it’s unlikely to leach, particularly because Burke’s regulations are 10 times more stringent (at 0.05 parts per billion) than those in California, which has the most stringent water/VOC regulations in the country, and that their product must pass the NFS 61 standard test, which is less stringent than California’s requirements. For other products, he says it depends on the “cake mix”—what’s in the resin.

Cost comparisons between geomembranes and rigid structures indicate that flexible membrane covers are as much as 65% lower than rigid construction and that for tanks over 10 million gallons, the difference is even more significant.

Burke CSPE liner longevity is similarly favorable when compared with other membranes: 30 years versus 15 years, Roades calculates, if properly maintained. “Coatings need recoating every 10 years,” he points out, adding, “It’s a hell of a product, but a bad business plan!”

The membrane works on concrete cisterns and is attached by drilling a hole in the concrete and adding a stainless pin and stainless batten bar. “We haven’t done many metal tanks because of attachment issues with the batten system,” acknowledges Roades. However, he says the membranes can be used on wooden tanks, common on ranches and vineyards in Napa.

Induron produces NSF 61-approved epoxy tank linings for water storage.

A LINER THAT GROWS ON YOU

Once a steel tank is breached and you get to the substrate, it oxidizes and rusts where water and oxygen meet. To prevent that from occurring, AmTech Tank Lining provides coatings and linings for water tanks used for potable water and emergency fire suppression, and for holding tanks for daily use. “We’re talking big steel tanks that are lap-welded or bolted with a lot of protrusions,” says Rob Pearlman, senior engineer.

Durachem 580 PW, a proprietary product, is used on steel and concrete tanks for potable water. Developed in response to a request from the Army Corps of Engineers to stop the weeping through concrete, it’s not a coating, Pearlman specifies: “It’s a lining.” He describes the NFS 61-compliant lining as being “like Tupperware for your tank” with its 500–1,000 psi adhesive. Cross-linked polymers provide structural strength by forming a monolithic shell. “It’s one surface. It’s like you’re building a tank in a tank.” The result is no blistering or chipping. “There’s no chipping like thick-mil-coating.”

Applied 1⁄16 inch to 1⁄8 inch thick in a high-temperature, high-pressure process, the superheated material goes on in a minute. One of the advantages is the structural integrity it provides. Another is its ability to go on surfaces that paint might not go on. It also lasts longer in temperatures up to 180°F.

Frac tank liner and cover

For even higher-temperature applications, AmTech offers other coatings, such as Hydra Stone cement lining for the type of hot water tanks commonly used in hotels. Pearlman mentions one major hotel that had sheets turning orange in the laundry because rust had leached into the water from their old tanks. He says that won’t happen with AmTech liners.

It’s not a topical sealant, he emphasizes. It is applied directly to the concrete tank and literally grows through it. It permanently waterproofs concrete internally, he explains, and is FDA-approved for food service process water.

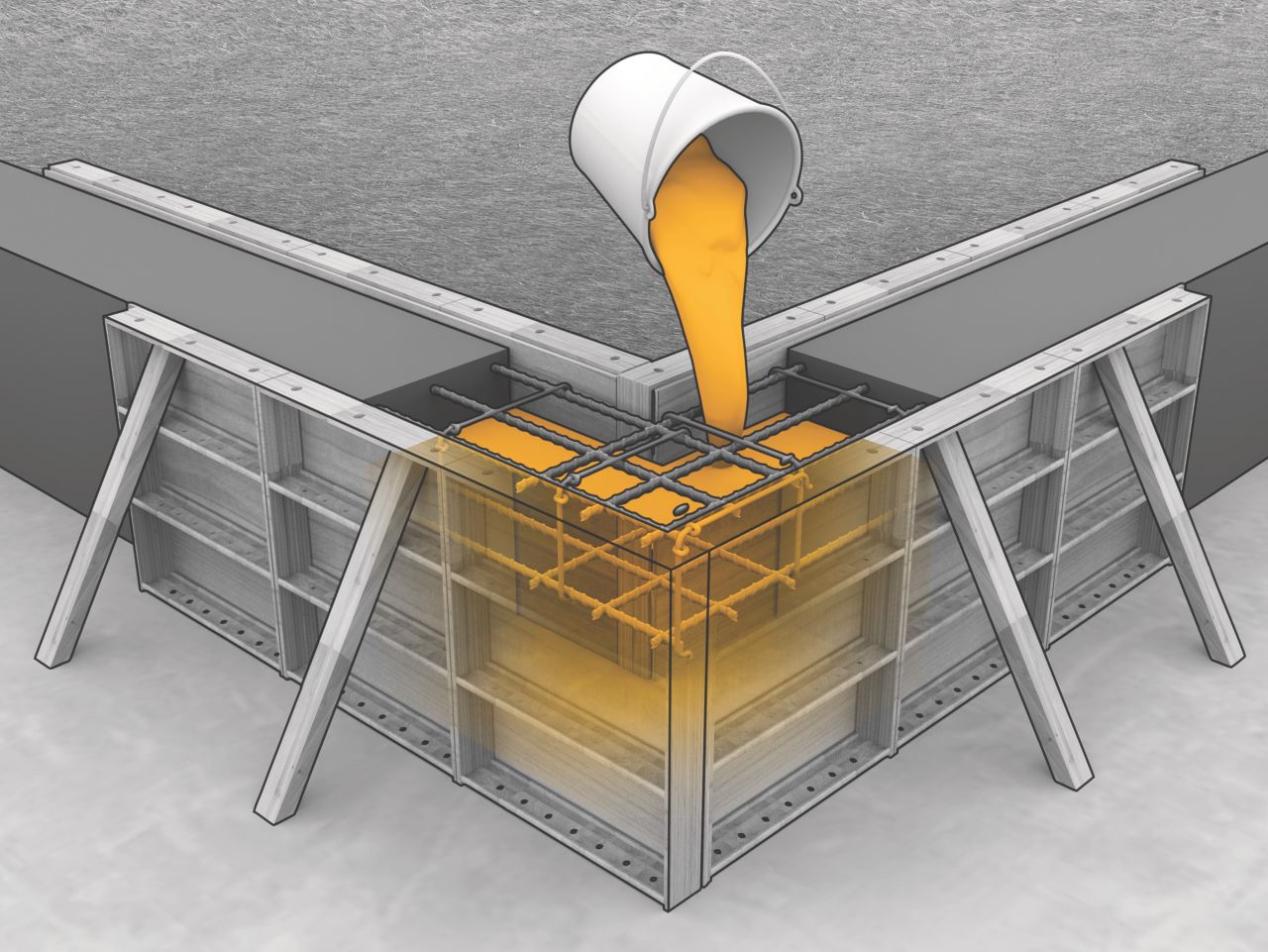

PREPARATION AND APPLICATION

Weather conditions are very important when applying any coating. Parameters include humidity, dew point, and temperature—both ambient and of the steel. Although some products are directly applied with minimal preparation, curing time for all depends on weather—except for those products that can cure underwater.

It begins with preparation of the surface— either sandblasting or pressure washing. Spots and isolated areas can be addressed by sanding down and touching up with a brush or roller.

When priming or sandblasting as part of tank preparation, Hugh Haire, vice president of operations, Pittsburg Tank & Tower Group, suggests avoiding humidity or it will flash. He also advises paying attention to wind direction in order to keep overspray away from critical areas.

“You must use NFS 61-approved products for potable water so there’s no leaching,” he states. Even with approved products, proper cure time and ventilation are essential. “VOCs are released if [the product doesn’t meet] federal standards. New York and California are more stringent.” In order to properly cure linings, it’s crucial to monitor temperature, time, and inner movement.

For those states and anyone wanting to use it, Haire recommends a plural component pump: the A and B sides mix in the gun. “Applicator equipment is changing,” he explains, noting that Pittsburg Tank & Tower makes applicators for field-ground storage tanks and performs maintenance on elevated water tanks—steel, bolted, concrete, and wood.

He also mentions a new Sherwin Williams epoxy that is a urethane hybrid—a one-coat primer and finish that will shorten application time. Products with 100% solids have extremely fast setup times, he says. There is less waste because there’s less product in the line.

Haire compares products, from an NSF-approved epoxy for potable water tanks at 4–6 mil per coat to a rubberized CIM product at 40–60 mil to enamel and polyurethane exterior paints at 2–4 mil. He cautions that if some paints are applied too thick, they can crack.

If the inside of the tank needs painting, it’s possible to bring in temporary tanks and replumb the system, but Haire estimates that the equipment will cost $40,000–$50,000, plus another $4,000–$5,000 for pumps.

Whether applying a coating or a lining, and no matter what type of tank, it all starts with routine inspections by a third party. They can be done dry or robotically, on a schedule, or on demand, but they should be done as part of general maintenance and upkeep. “To avoid leaching, get third-party testing done,” underscores Hood.

REFERENCES

www.nsf.org/services/by-industry/water-wastewater/municipal-water-treatment/nsf-ansi-standard-61